THOUGHT LEADERSHIP

Safer hydropower stations for safer workers

“Practices related to dam safety are well-defined and accepted throughout the world. However, hydropower safety encompasses more than just the dam … while hydropower safety is of critical importance, there is little shared knowledge on good practices around the concept of hydropower safety.” – International Hydropower Association

Hydropower stations can pose significant safety risks to those who work in them, but there is no excuse for injury or death in our workplaces. Whatever the history or location of the hydropower station, safe plant and safe work practices are critical.

Developers, owners and operators of hydro plant all need a strong commitment to workplace health and safety, and the insight and vigilance to control safety risks. As the saying goes, ‘safety doesn’t happen by accident’.

The hazards of hydropower stations

Some of the hazards at hydropower stations differ from those at thermal power stations or commercial installations. For example, hydro stations typically have limited access and no natural lighting, lower floors are often below the outside water level, and many are underground.

Hydropower hazards include fire, explosion (e.g. of pressure vessels), electrocution, flood, entanglement, slips and falls, chemicals (e.g. sulfur hexafluoride, hydrogen sulfide) and hazardous products (e.g. asbestos), and asphyxiation (e.g. carbon dioxide).

The level of risk presented by each hazard is a combination of its likelihood of occurring and the consequences if it did occur.

Seven ways to make a hydropower station a safer place

Designing safety into hydropower stations

When designing and implementing a new hydro scheme, or when upgrading an existing station, we need to carefully consider the standard of workplace health and safety to be achieved and the scope of work necessary to achieve it. This means understanding the relevant legislation, building codes and standards, and the requirements of the insurer; and being clear about the responsibilities of all the parties involved (such as the designer, developer, owner and contractors).

But while standards, codes and guides are a good starting point, the final solution needs to be tailored for the particular circumstances and level of risk. Safety systems for hydro plant can be complex and sophisticated, but they can also be as simple and robust as appropriate for the hydro facility being protected.

The primary consideration should be to provide safety facilities to get personnel out of a hydro station safely before conditions inside become dangerous. The second consideration should be providing facilities to get people out safely after conditions become dangerous. Only thirdly do we think about safety facilities to prevent damage to plant.

Planning ahead to control risks

A general approach taken to minimise workplace risks to the lowest practical level involves planning ahead for prevention of workplace accidents, injuries and illnesses, by ensuring that systems of work are safe, equipment is safe and properly maintained, and employees receive health and safety information and training and are properly supervised.

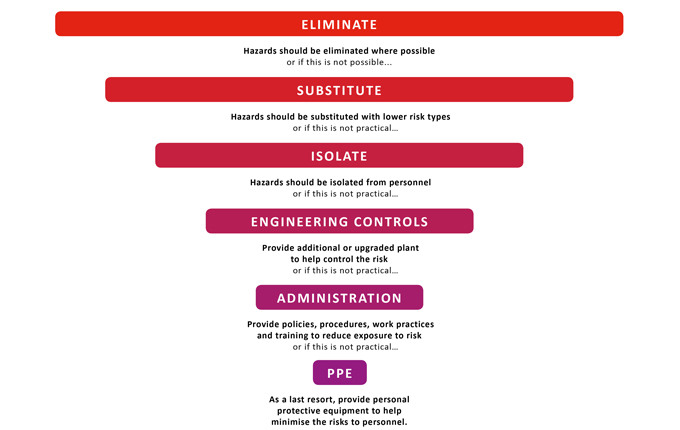

This approach is usually expressed through a ‘hierarchy of controls’:

Safety upgrades for older hydropower stations

Typically, new hydro stations are well designed and comply with appropriate safety standards and local building codes. Larger hydro stations can have safety systems as complex and thorough as those in modern multi-floor commercial buildings. However, older hydro installations were often designed with little regard to safety, and now need urgent attention to comply with modern workplace health and safety standards.

While safety facilities are readily incorporated into new hydropower schemes, they may be more difficult to retro-fit into existing schemes. The scope of work will need to take into account the interfaces with existing facilities and the tailoring required to suit the specific site and location.

Sharing our hydropower safety insights

Entura is part of Hydro Tasmania, Australia’s largest producer of renewable energy and manager of more than 30 hydropower stations with an enviable safety record. As a specialist power and water consulting firm, we’ve applied this real-world experience of designing safe hydropower stations and upgrading older plants to meet modern safety standards as we work with clients all over the world to improve the safety of their assets.

In our experience, these four very important aspects of hydropower safety should be considered as a first step towards building good practice for designing and operating safer hydropower stations:

| Station evacuation | Whatever the nature of the crisis, people must be able to get out of a hydropower station safely. All stations should have at least two independent ways to exit. If one route becomes inaccessible, an alternative emergency escape route should always be available. Adequate lighting is essential for emergency escapes. |

| Flood protection |

Hydropower stations can and do flood. Failure of drainage pumps can lead to a slow increase in the water level and eventual flooding of the station. Alternatively, a plant failure and leakage that drainage pumps cannot manage can cause rapid flooding of the station. This makes high-water-level alarms, flood alarms and evacuation alarms a necessity for life safety. Flood protection schemes can be implemented to automatically close intake gates or hilltop valves and keep turbines operating to attempt to drain the headworks and penstocks of water to control flooding, and to automatically stop hydro plant before the water levels become critical. |

| Fire and smoke control |

For life safety, we need to detect fires as early as possible, prevent them from spreading, alert all personnel, and provide safe and well-lit means of evacuation as soon as possible. Smoke control and ventilation are also extremely important. Fire will rapidly fill a hydro station with thick, black, acrid smoke, which is often a far greater hazard to personnel than the fire itself, as it obscures vision (preventing occupants from finding safe escape routes, as well as hindering search and rescue operations). It can also asphyxiate or poison people well before the temperature of the fire or smoke causes injury. A holistic fire protection system needs to attend to the full range of passive measures (e.g. fire-rated construction materials and methods), active measures (e.g. sprinklers, venting, fire-fighting equipment) and operational measures (e.g. plans, systems and training for fire prevention and response). |

| Emergency and crisis and management |

Safety at hydro stations involves more than simply having the correct equipment or hardware present at the site. It involves an ongoing commitment by the owner, management, operator and employees to provide and maintain a safe and healthy work environment. This commitment should be documented in writing and form part of a workplace health and safety policy supported by safe work systems and documentation. These should include a written risk control program and fire protection program, hazard register, site induction procedures, attendance boards, permit to work systems, local safety teams, and a detailed crisis and emergency plan. |

To discuss how Entura can assist you with assessing hydropower station risks or developing a hydropower safety program, please Shekhar Prince on +61 412 402 110.

This article was written by Ambrose Canning, Entura’s Principal Consultant, Mechanical Engineering (retired 2025).

MORE THOUGHT LEADERSHIP ARTICLES

12 October, 2015