THOUGHT LEADERSHIP

Dam Emergency Dewatering Outlets: A ‘Must Have’, or a ‘Nice to Have’?

One contributing factor for dam safety is the ability to rapidly lower the water level in an emergency. But how can dam designers and owners appropriately determine the need for a dewatering outlet or its optimum size in the absence of a consistent international standard?

Dam safety must begin long before the dam is filled

Dam owners are responsible for the continued safety of dams throughout their life cycle, and for maintaining acceptable levels of risk exposure for downstream communities. As we’ve highlighted in previous articles, dam safety can protect lives and drive efficiencies, having a robust approach to dam safety management must be a top priority for dam owners, regardless of the size of the dam.

A dam safety program should be underway before a dam is filled for the first time, especially if there is significant downstream consequences. This dam safety program should include details such as operational instrumentation, regular routine inspections, and personnel and systems in place to make the necessary decisions should any unusual observations occur. The dam safety manager is a key role required to escalate and make decisions in relation to this. In addition, the key dam safety documentation should have been prepared, including a dam safety management plan, dam surveillance plan, dam operation and maintenance plan, dam safety emergency plan, and evacuation plan. We’ve talked about these elements previously in our ten-point plan for safer dams.

Triggers for dewatering

During unusual events such as the first filling of the dam, major floods or major seismic events, the dam needs heightened scrutiny. If visual inspections and instrumentation monitoring indicate any sudden increase in dam deformation, leakage or internal pressures, it is important that an incident is raised and investigated. If the change progresses and may be developing into a dam safety incident, the risk mitigation strategy may be to reduce the reservoir level (i.e. the water loading on the dam).

To rapidly reduce the reservoir level, a low-level, emergency dewatering outlet is usually needed.

The need for an emergency dewatering outlet

It is good practice to provide an emergency drawdown facility in a dam. This enables the reservoir level to be reduced in a dam safety emergency, which lessens the loading on the dam and the volume of water behind the dam.

The purposes of an appropriately sized low-level outlet are (1) evacuation of the reservoir if emergency conditions occur, or inspection, maintenance and repair of the dam and appurtenant works that are normally submerged, and (2) controlling the rate of reservoir rise as required by reservoir filling criteria.

There are examples in Australia and internationally in which no emergency dewatering outlets are incorporated into the dam, or the total outflow capacity provided is inadequate. Yet there is no consistently adopted international standard for the requirement and sizing of an emergency dewatering outlet. This gap in consistent guidance is of concern, given the importance of dewatering outlets for dam safety.

Lack of consistent international standards for dewatering outlets

The International Commission on Large Dams (ICOLD) provides no reference to a specific drawdown rate; however, a number of its technical bulletins do refer to a bottom outlet to empty a reservoir.

ICOLD Bulletin 49a – Operation of Hydraulic Structures of Dams (1986) states: “It is very important for the dam operator to have outlets enabling the reservoir to be drawn down. While bottom outlets do not readily fit into some sites (as with very large reservoirs on very large rivers), there are still many cases where their absence is regrettable or where they are too small or ill designed … Besides allowing the reservoir to be emptied in periods of low river flow, bottom outlets can also provide fine control of the reservoir during the most critical period of a dam’s life, during the first filling, and draw down the level whenever necessary thereafter.”

Some guidance for emergency drawdown was given by the United States Bureau of Reclamation (USBR) in 1990, suggesting drawing down the reservoir volume to either 10% of the storage or 50% of the height in 1 to 4 months.

However, as these guidelines suggest, it may be impractical to provide the drawdown capability to meet the criteria and guidelines for certain projects. Some reservoirs may be just too large for short-term evacuation. The USBR guideline recognises that decisions relating to emergency dewatering outlets should be made considering the risks that the outlet would help to mitigate and the costs to include such an outlet.

Promoting a risk-based framework

A more recent guideline on emergency dewatering outlets for dams is the UK Environmental Agency’s Guide to Drawdown Capacity for Reservoir Safety and Emergency Planning (2017). This document provides guidance on a consistent methodology for assessing the adequacy of existing drawdown capacity at reservoirs in the UK, based on the judgement of an experienced dam engineer. This judgement should consider the proposed basic minimum recommended standards, the consequence of dam failure, the vulnerability of the dam to rapid failure, the time it may take to detect symptoms of failure and to activate drawdown, the time required to draw down the upper third of the reservoir, the ability to keep the reservoir down for repairs, and precedent practices.

The guidelines promote a risk-based assessment, considering options for mitigating those risks. The guidance document states: “The cost of increasing drawdown capacity is compared to the reduction in risk to life achieved, and only implemented where the cost is proportionate”.

These UK guidelines therefore encourage a risk-based framework for evaluating the drawdown capacity of any emergency dewatering outlet. However, the UK has very few very large reservoirs on large catchments, and the guidance provided may therefore not be applicable to very large reservoirs.

What about larger reservoirs?

The challenge in applying the existing international guidance is when the reservoir is very large and/or the dam is located on a very large river. These larger reservoirs are often associated with hydropower projects. This is recognised in the guidance documents discussed above; however, an alternative approach is not provided.

Both the UK and USBR documents do suggest, though, that the reduction in risk created by an emergency dewatering outlet should be weighed against the cost.

Given that an emergency dewatering outlet is not always possible or practical (particularly for large reservoirs), how can risks be mitigated in other ways?

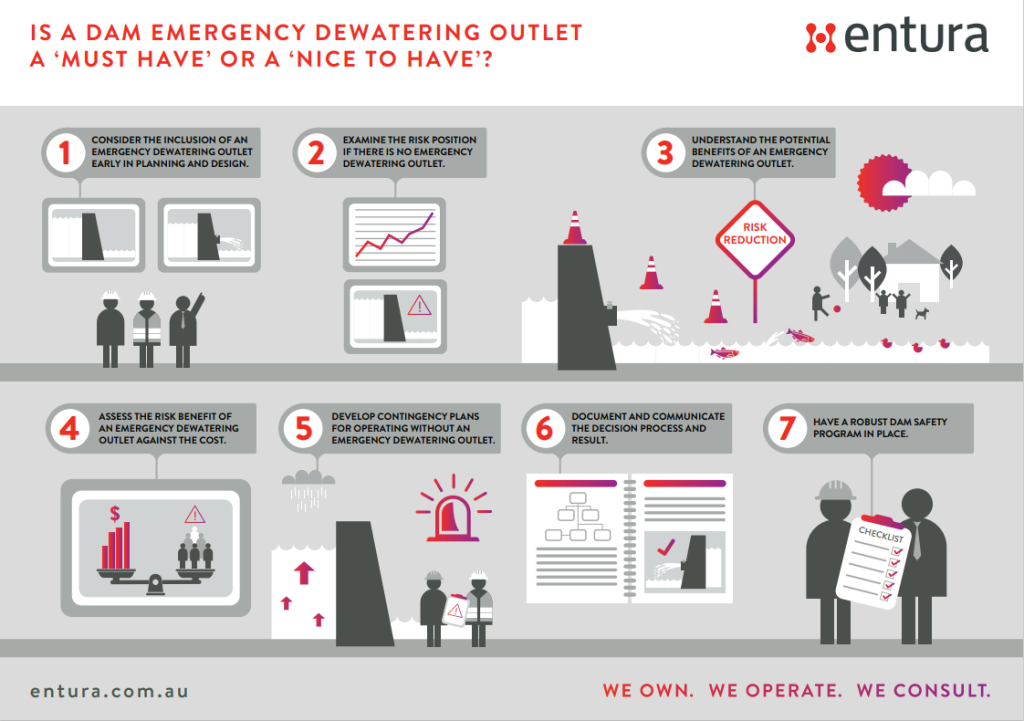

Seven considerations for safer dewatering decisions

When determining whether a dewatering outlet is a ‘nice to have’ or a ‘must have’, systematically consider the alternatives through a risk-based framework and document the decision. With or without an emergency dewatering outlet, it is crucial to develop a robust design, fully consider dam safety, and appropriately mitigate risks to acceptably low levels.

Think about these seven points:

- Consider the inclusion of an emergency dewatering outlet early in planning and design.

It is often easier to incorporate an emergency dewatering outlet into the dam’s general arrangement in the early stages of the design process, rather than later when the dam type has been locked in and all the various components (spillway, intake, diversion) have been located and defined. If it is easy to incorporate, it is good practice to include.

- Consider the risk position without any emergency dewatering outlet.

The main purpose of the emergency dewatering outlet is to be able to take some mitigating action in a dam safety emergency. It is therefore important to determine the risk position of the dam without an emergency dewatering outlet, and evaluate whether this risk is acceptable based on the downstream consequences. Every dam site is unique, so all potential failure modes for this particular dam need to be considered in the risk assessment. If the risk position is not acceptable, alternative options for mitigating the risk should be considered and built into the design and/or operational procedures. Adopt a robust design with sufficient redundancy to mitigate the risks identified through the potential failure modes analysis.

- Understand the potential benefits of an emergency dewatering outlet.

Before deciding that it is too costly to construct an emergency dewatering outlet, at least consider the potential benefits. Gain an understanding, from a holistic project perspective, of the hazards/risks that an emergency dewatering outlet could mitigate. Consider the importance of controlling the rate of initial filling of the reservoir, the ability to evacuate the water from the reservoir at a meaningful rate to make a difference in a dam safety emergency, and the ability and ease of repairing issues below reservoir level by lowering the reservoir rather than undertaking repairs underwater.

- Assess the risk benefit of an emergency dewatering outlet against the cost.

Carefully evaluate the reduction in risk due to the presence of an emergency dewatering outlet compared to the cost – is there a strong justification or not? Even if a full-capacity dewatering outlet is not possible, consider the risk benefit against cost for what is Compare the risk difference ‘value’ with the cost of the emergency dewatering outlet. This will inform a conversation about whether the ‘value’ justifies the cost, which is a strong basis for a sound decision.

- Develop contingency plans for the future.

If there is no emergency dewatering outlet that can enable the reservoir to be emptied for repair works, consider what repair actions may be required during the life of the dam. Ask the questions: What might go wrong? How would we rectify that if we cannot dewater the dam? and Is there anything else that we could build into the design to make this easier? This is ‘safety in design’ thinking, and documenting these high-level contingency plans in the operation and maintenance manual will help those managing the dam in the future.

- Document and communicate the decision.

Document the entire decision process and include the reasons for any decision. All key stakeholders should be aware of and accept the ramifications of any decision. Your organisation should have a robust process in place to assist this decision making process and ensure appropriate consideration in relation to an emergency dewatering outlet. The appropriate dam regulatory body will also need to support and accept the decision.

- Have a robust dam safety program in place.

Any dam with significant consequences downstream (as defined by ANCOLD Guidelines, or similar) should have an appropriate dam safety program in place. If an emergency dewatering outlet is not part of the facility, it is important that the other dam safety risk mitigation strategies identified in point 2 are implemented. The dam safety emergency plan should clearly state the actions to be undertaken in a dam safety emergency, as well as who is responsible for them.

A dam safety emergency dewatering outlet can enable a dam owner to be proactive in a dam safety emergency, and help to maintain or reduce the dam safety risk. As such, it is always a nice thing to have as part of a dam facility, and it should, ideally, be included in any new dam. However, if it is not possible or practical to include a dewatering outlet, be sure to make careful, considered decisions based on a comprehensive understanding of risks and consequences.

If you’d like to discuss how we can assist you with planning, designing and constructing safer dams, please contact Richard Herweynen, Paul Southcott or Phillip Ellerton.

About the author

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

February 17, 2022