Dams are crucial to climate change response and the energy transition

At the recent ICOLD meeting in Gothenburg, Sweden, dam engineering experts from across the globe came together to share knowledge, discuss trends and issues, and engage with each other. One important topic of discussion was the role of dams in the international response to climate change and what that will mean for the dams industry. Richard Herweynen, Entura’s Technical Director, Water, shares his thoughts on this topic here …

Why will dams play a critical role?

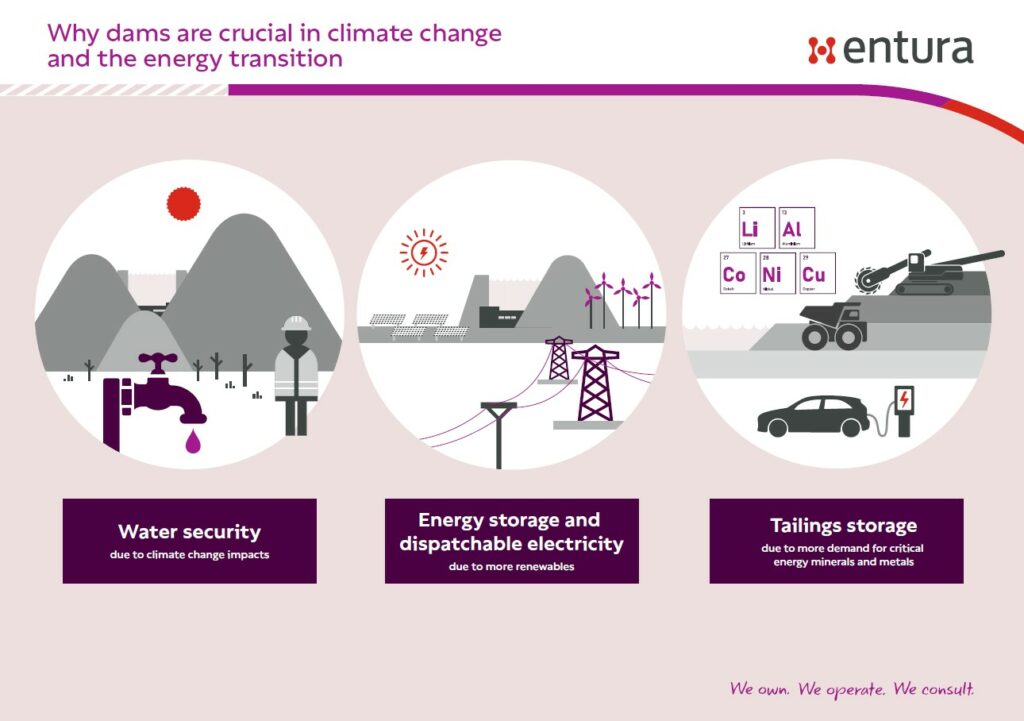

Three major reasons why dams will be crucial in the climate change response and energy transition are water security, dispatchability of electricity, and tailings storage.

- Water storages will be vital to provide the same level of water security

Water security is essential for humanity. With greater hydrological variability due to climate change, more storage will be needed to provide the same level of security of water, food and energy. Water storage is a fundamental protection from the impacts of a changing climate, safeguarding the supply of water, and the water–food–energy nexus, even during extended drought.

The effects of climate change are predicted to increase and to result in greater magnitude and frequency of hydrological extremes, such as prolonged droughts and significant floods. With prolonged drought, inflows to storages will reduce. If demand remains the same, stress on existing water storages will increase.

Water storages are used to regulate flows and manage this variability: storing water when there are high inflows (or floods) and then using this stored water during low inflows (or droughts). Dams are used to create these vital water storages.

- Hydropower and pumped hydro energy storage (PHES) are critical for the energy transition

A key response to climate change is the decarbonisation of the electricity sector through renewable energy. Wind and solar power now offer the lowest cost of energy, have low ongoing operational costs, and emit the least greenhouse gases across their lifecycle – and therefore hold the greatest potential for rapid decarbonisation of the energy sector. Of course, wind and solar PV output vary according to the weather and the time of day – but the electricity market needs the supply of electricity to match demand, or for these renewables to be dispatchable.

Energy storage is the key to smoothing out the variability of renewable energy generated by solar and wind. The power and duration of the storage are the two key variables in determining the most suitable solution. Low-power, short-term storage is currently more cost-effective using batteries, but longer periods and larger power requirements are likely to rely on bigger storage options, such as pumped hydro energy storage (PHES) and traditional hydropower. Smoothing out the daily variability in renewables can be achieved effectively through pumped hydro. Dams are used to create the water storages used in both traditional hydropower and PHES.

- The transition to renewables will demand more minerals and metals

The global energy transition will demand a major increase in renewable energy technologies – which in turn will require more of the ‘critical energy minerals’ and metals. The rising need for minerals such as copper, aluminium, graphite, lithium and cobalt will not be able to be met by recycling and reuse alone. Therefore, extraction and storage of minerals from mining operations will be essential to sustain the renewable energy transition.

According to a report by the World Bank Group, the production of minerals such as graphite, lithium, and cobalt could increase by nearly 500% by 2050 to meet the escalating demand for clean energy technologies. It is estimated that over 3 billion tonnes of minerals and metals will be necessary for the deployment of wind, solar, geothermal power and energy storage, all of which are vital for achieving a sustainable future with temperatures below 2°C.

However, this need for mining activity comes with a special responsibility for sustainable practices, including the proper management and storage of mining waste. Rock, soil and other by-products are left behind after the desired minerals have been extracted from the ore. Tailings facilities store this waste, playing a crucial role in mitigating the environmental impact of mining operations. Dams, in particular, are commonly used to create these facilities, as they provide an effective means of containing the waste.

Dams used in tailings facilities are designed to withstand the weight and pressure of the waste materials, prevent seepage of contaminants into the surrounding environment, and take into account factors such as stability, erosion control and water management. Dams that are well designed, constructed and monitored, adhering to stringent environmental and safety regulations, can help prevent the spread of mining waste into nearby water bodies, reducing the risk of water contamination and protecting aquatic ecosystems.

Working towards ‘good dams’

While there have certainly been some examples around the world of dams that have had adverse impacts, it is clear that dams will play a critical role in the international response to climate change and the decarbonisation of the energy sector. It’s therefore vital that dams are planned, constructed and managed appropriately and safely. With increasing understanding of impacts and far greater sophistication of internationally accepted sustainability protocols, it is now up to developers and planners to heed the lessons of the past and find the right dam sites for nature and communities.

It is important that we ensure the safety of existing dams as well as the safety of any new dams. Examples from around the world demonstrate the devastating consequences of dam failures. Safety must be every dam owner’s key concern, and should be managed through an active dam safety program.

Of course, the larger the portfolio of dams an owner is managing, the greater the demand on their resources; however, it is critical that dam safety risks for water storages and tailings facilities are managed appropriately across dam portfolios to protect downstream communities. The Portfolio Risk Assessment process increases the focus on potential failure modes and risk as drivers of the dam safety program and as the basis for deciding priorities for allocating operational and capital resources.

It will also be vital that dams engineers, owners and operators keep up to date with the latest developments in the dams industry worldwide through continuous learning and important global forums such as ICOLD.

If you’d like to talk with Entura about your water or dam project, contact Richard Herweynen.

About the author

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

Planning sustainable water infrastructure in a changing world

In an already water-stressed world and a rapidly changing climate, water is increasingly precious. To manage and control this vital resource, we must create and maintain safe, reliable and sustainable water infrastructure – and such a challenge calls for good planning.

The International Commission on Large Dams is working towards releasing new guidance for water infrastructure planning – and Entura’s Richard Herweynen is a member of the Technical Committee looking to develop a new ICOLD Bulletin on planning. In this article, Richard explains the importance and evolution of planning approaches.

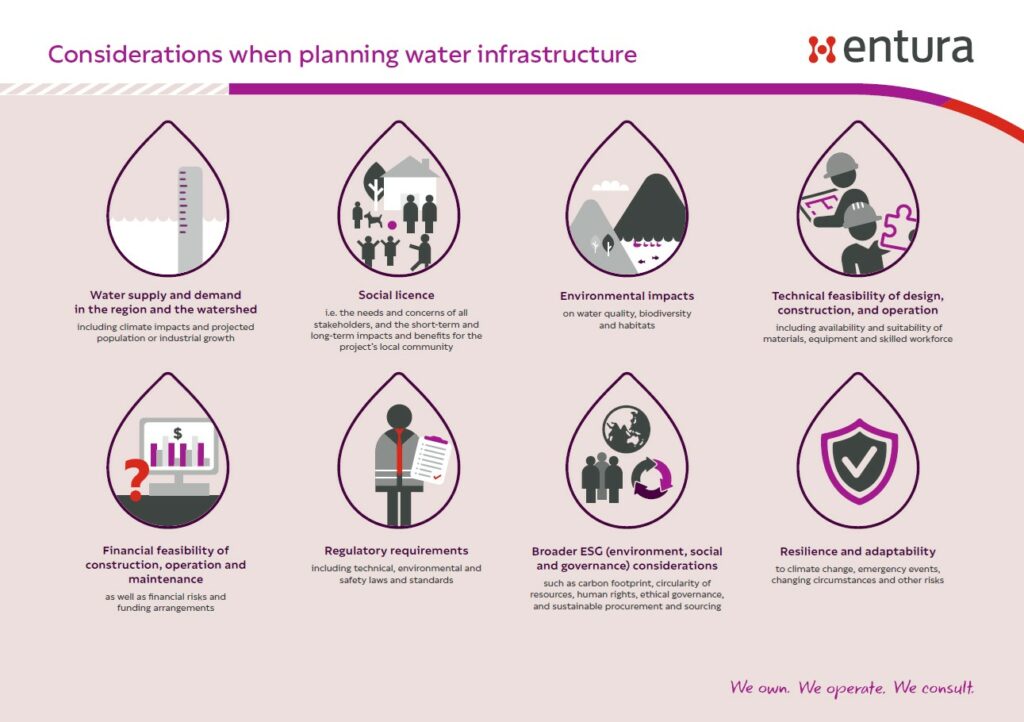

Water infrastructure projects deliver the dams, treatment plants, irrigation systems and distribution networks that provide water for homes, food production, industries and emergencies. They also create the structures integral for mitigating the effects of floods and droughts. But to maximise the benefits of this infrastructure, projects must be planned, engineered and managed for effectiveness, safety and sustainability.

These projects are far too important to approach in a haphazard way. Planning offers a structured, rational approach to solving problems – and it is the start of the ‘pipeline’ for addressing water resource needs and competing demands. In fact, for civil works programs, everything begins with planning.

Without a good plan, where are we?

Without careful planning, it can be difficult to achieve creative, cost-effective solutions to water needs. The planning stage helps decision-makers identify water resource problems, conceive solutions and evaluate the inevitably conflicting values inherent in any solution. Planning is best done by a team that brings together specialists in many of the natural, social and engineering sciences.

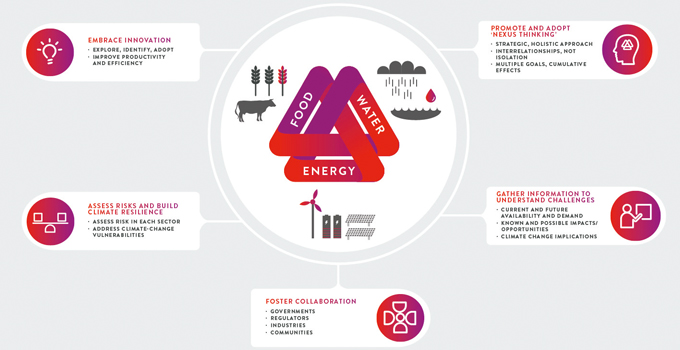

At the planning stage, all of the following points should be thought through:

Guidance for better planning

In 2007, I became the ANCOLD-nominated member on a new Technical Committee for the International Commission of Large Dams (ICOLD) entitled ‘Engineering Activities in the Planning Process for Water Resource Projects’. In 2009 we put forward a position paper setting out an ‘Improved Planning Process for Water Resource Infrastructure’ based on ‘comprehensive vision based planning (CVBP)’.

At the next ICOLD Annual Meeting in Sweden in June 2023, our committee will be meeting to work on an updated framework that takes into account the rapid change we’ve witnessed over the last decade and the many cross-cutting issues that are impacting the planning process, such as risk-informed decision-making, climate change, sustainable development, environmental concerns, and river basins/systems.

What is ‘comprehensive vision-based planning’ (CVBP)?

Before we talk about updates, let’s take a quick look at our existing approach to CVBP, as articulated in 2009.

CVPB is a comprehensive, transparent planning process based on a shared vision for sustainable water resource development. It aims to achieve a better ‘triple bottom line’ outcome, with optimum economic, social and environmental outcomes.

Whereas many past projects were planned on a case-by-case basis, CVBP looks beyond the immediate project to the broader regional vision and watershed goals (which may also cross national borders), taking projected changes in water supply and demand into account. It draws on integrated water resources management (IWRM) to consider multiple points of view about how to manage water and to view each water infrastructure project in relationship to the other existing infrastructure in the region.

CVPB also incorporates much greater attention to the realistic options and cost-benefits of mitigation of environmental impacts – and it draws in more interdisciplinary engineering, cost estimating, and stakeholder/community engagement.

CVBP is, therefore, a holistic, integrated and collaborative approach to planning and a much-improved pathway towards successful outcomes.

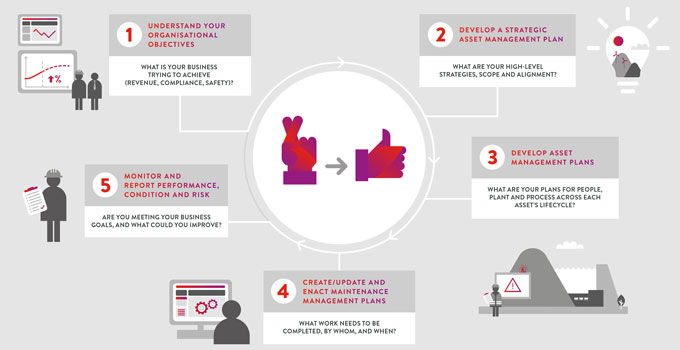

The 8 steps of CVBP

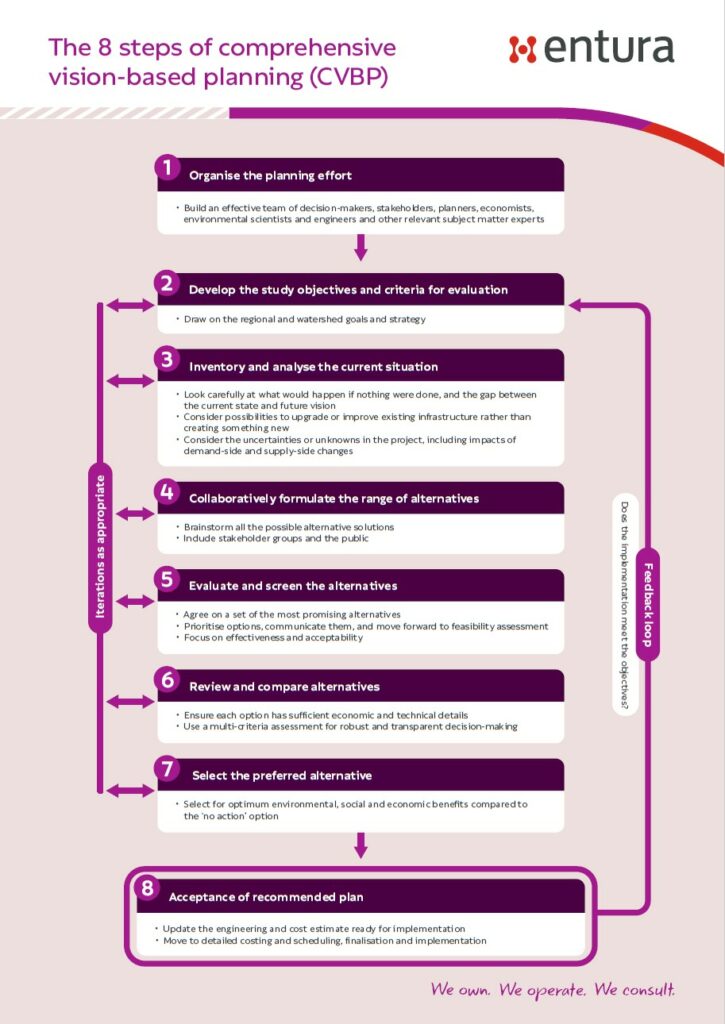

As currently articulated, CVBP has 8 defined steps – but it’s an iterative process in which steps 2 to 7 are repeated multiple times, as necessary. The 2009 ICOLD bulletin goes into much greater detail than we can in this article, but this will give you an overview:

Changes moving forward

It is time to update the planning process and guidance in the light of the rapid changes we are experiencing in our environment, innovations in technologies, and an increasing awareness of sustainability and ethics.

In the past, much water infrastructure has been planned within a reasonably near-term political and social lens and timeframe, and from a perspective of relative stability. But we know that change is constant and rapid, so our planning approaches need to shift to an even greater appreciation of uncertainty, risk and the intensifying potential for extreme events. There is also an urgent need to apply a deeper and broader awareness of the many considerations that make for greater environmental, social and economic sustainability.

Important factors here will be an uplift in stakeholder involvement and governance, a very clear focus on the costs and benefits that can’t easily be quantified or monetised, and reinforcement of the fundamental principle of ‘do no harm’.

It will also be important to take an adaptive approach to regional planning objectives, with a strong awareness of different regional and cultural values, goals, expectations, methodologies, financing arrangements and roles of government.

We should expand the planning scenarios to also explore non-structural options, dam removal plans, and scenarios based on failure modes. We also need to improve early data collection by finding and filling data gaps, improving the ways in which we preserve historical information, and improving data portrayal.

It is very important to involve the right people. Ideally, the planning team should be more than ‘multi-disciplinary’ or ‘interdisciplinary’. It should aspire to be ‘transdisciplinary’, in which all disciplines work seamlessly and collectively and achieve a level of insight that is ‘greater than the sum of its parts’.

This year, our Technical Committee will continue to build on some of these elements as we review and rearticulate CVBP, working towards a new ICOLD Bulletin to guide water infrastructure planning.

In a changing world, our approaches to infrastructure cannot stagnate. Designing, articulating and applying new planning frameworks is an important step towards creating and maintaining the sustainable, reliable water infrastructure our planet so urgently needs.

If you’d like to talk with Entura about your water or dam project, contact Richard Herweynen.

About the author

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

Field investigations in remote locations – factors for success

Conducting field investigations in remote areas is no ‘walk in the park’. On top of the investigation activities themselves, there are the complex logistics of getting personnel and equipment into hard-to-reach places, the imperatives of maintaining safety and managing community expectations, and the significant challenge of conducting works but leaving minimal impact on the landscape.

‘Leave no trace’ may not be too hard a goal when you’re heading off on a simple bushwalk. However, when it comes to conducting field investigations in remote areas with heavy specialist equipment, ‘treading lightly’ can be extremely challenging – but it is something Entura is committed to.

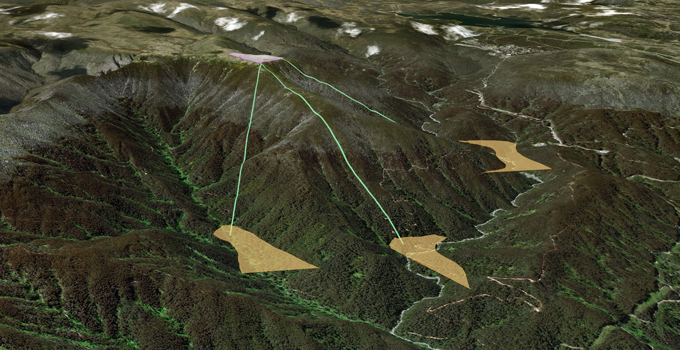

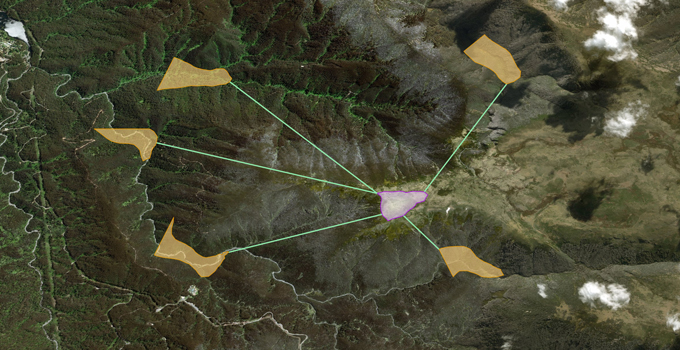

Entura has recently delivered geotechnical investigations for Hydro Tasmania’s feasibility study into the potential for pumped hydro development in some very rugged, remote country in western Tasmania. This is how we did it, and some success factors we can share for field work in these conditions.

Planning

Planning and contract expertise is paramount for successful execution of any project, but particularly so in remote locations. It’s important to take the time at the very beginning of a project to really understand the entirety of the scope and the project objectives. To reduce the risk of unwelcome surprises and unwanted variances, spend enough time on the ground before the works commence so that you can be sure that all the elements have been considered.

This is also the time to gain a full understanding of all the permits and approvals that will be required, the lead time to achieve them, and the range of agencies and key stakeholders who need to be engaged right from the earliest stages.

It will take time and consideration to engage carefully with all contractors to understand their expertise, capability and willingness to undertake the works; but the effort to find the right contractors will be more than repaid by the improved outcomes.

Our project involved multiple drilling investigations to 600 m in 3 separate and remote locations, including a deep ravine located between Lake Plimsoll and Lake Murchison in the heart of Tasmania’s West Coast. The goal was to achieve a clear understanding of geological conditions within the region, which had previously been identified as a fault zone. Our planning needed to encompass all the necessary desktop studies to understand as much as possible about the environment, the stakeholders, the regulations and requirements, and the conditions our contractors could expect, all in advance of sending personnel and equipment into the remote site.

The key to our success in the project was leaving no stone unturned in the planning phase, and using these preliminary insights to choose the right contractors for the job, with the right equipment and skills to achieve our objectives. When things go smoothly and look seamless or simple from the outside, it is usually because of the significant investment of effort in detailed, logical planning right at the start.

Site access

Remote access can be extremely difficult, so the success of a project will depend on establishing practical, efficient and low-impact routes at the earliest stages of planning. Time is money, so contractors will need the easiest and quickest access to the site that you can achieve without compromising on safety or the environment. This will need early and thorough engagement with land-owners to identify constraints, requirements and options. Selecting the best access options will rely on a deep understanding of the biodiversity and heritage values of the site through desktop analysis combined with intensive field observations and data collection.

We selected access routes using a variety of considerations, including what equipment would be required on site, the duration of investigations, the significance of data we gained in the planning stage, analysis of the costs and benefits of options, consideration of the longer term benefits to the land-owners, and consideration of future works.

Ultimately we used a combination of access methods including foot tracks, temporary and permanent roads, and helicopter access. Again, it was crucial that we chose the right contractors who could cope with the conditions and understand the constraints. Our excellent local contractors were integral to our success.

Environment

Conducting works in a region of high natural values demands deep consideration of strategies to avoid or reduce long-term impacts and of what remediation efforts will be necessary and effective.

In one particular instance, we identified and implemented a range of strategies to create a 1.2 km foot-access track in a very sensitive and damp area that was likely to become muddy and highly degraded under the pressure of constant foot traffic during the duration of the works. To protect against this, we hand-cleared the site, developed suitable drainage channels, stabilised the banks, then deployed geo-fabric matting onto which we laid a top coat of clean and approved local woodchips. This innovative solution proved highly successful: it provided solid, safe and reliable footing, excellent drainage and made clearing up the site relatively easy and efficient as the woodchips could be wrapped in the geo-fabric matting, bagged and removed from the site. Once the works were completed, the cut-back vegetation was relatively unscathed, and was able to re-shoot and re-establish rapidly.

Stakeholder and community engagement

Continuous and inclusive community and stakeholder engagement, tailored to the particular community or stakeholder segment, is critical for the success of any project – and the earlier it begins, the better. In our project, we went out on the front foot, building a shared understanding of our objectives, making detailed information available and inviting stakeholders to raise any concerns with our team. We even facilitated site visits for key stakeholders to gain a fuller understanding of the works and build trust.

Many project proponents will tell stakeholders and communities that they want them ‘to come on the journey’ – but we walked the talk, inviting stakeholders to check our milestones, come along to inspect aspects of the work, and to share their feedback.

Cultural heritage

Over a sustained period, Hydro Tasmania has undertaken intensive desktop and field analysis of particular regions and their history. In addition to this rich database of information, Entura has access to specialist cultural heritage consultants who document heritage sites and support us to manage these sites in accordance within the appropriate legislation requirements. Early notification and thorough assessment early in the planning phase indicates whether a heritage site or specific location is likely to be encountered, which enables processes to be established to mitigate heritage risk, minimise site damage and, in some instances, plan for total avoidance and re-siting of works.

In our project, the early engagement of reputable consultants gave us confidence that any areas of significance had been identified. We clearly defined these areas of significance and protected them from any impacts from the works.

Water supply

Drilling investigations require a significant volume of water every day. But not all, if any, remote locations have a ready supply, and if so it’s usually some distance away. Geotech drilling investigations require up to 30,000L/day depending on ground conditions, so the ability to capture and re-circulate water and reduce sediment discharge to the natural environment is crucial in remote locations. Sometimes this needs a bit of innovative thinking to achieve.

Working in a naturally wet environment and on a hillside enabled us to trap natural run-off and control flow to a small header tank (44 gallon drum), then pipe the water to 3 x 10,000L tanks at a flow rate over 24hr period. Three sandbags, float switches and low-impact plastic irrigation pipe allowed us to supply the drill rig with water for 90% of its operation, only having to stop temporarily while drilling during a 5-day period without rainfall.

The creation of a small pond on a steep downhill slope minimised environmental impact downstream and allowed a steady flow of water to continue over the micro dam. The header tank minimised air locks, while tank float switches prevented overflow on the drill site.

By capturing water above the work site, we eliminated the need for extra foot tracks to the creek down in the valley or the need to pump and re-fuel a diesel water pump or to truck water in over 2 km.

Climate conditions

Projects sometimes can’t wait for the perfect time of year to commence. In Tasmania, this brings the challenges of adverse weather conditions and extreme events such as snow and bushfire – even within the same month!

Our remote projects faced these challenges, including frozen water pipes, snowed-in access routes and the risk of bushfire. Planning, watching the weather, and evacuation plans became a daily function.

At one particular location we soon learned that water freezing overnight in pipes could cause significant delays in the morning. Our quick solution was to drain the pipes at night to avoid the problem reoccurring.

To mitigate risks in hot conditions, we had safety processes and equipment in place, such as no-work orders in extreme hot and windy conditions, evacuation plans, safe areas, designated exits, fire pumps and satellite communications.

Safety

Safety should be a top priority on all worksites, and working in very remote areas involves an extensive range of safety considerations. Our workplace health and safety plan provided an overarching document to support the program of work, providing a framework of safety planning, processes and equipment, and careful consideration of the range of potential controls. Each of our contractors developed their own safe work method statement for their own tasks.

In our project, the key identified risks were driving long distances in remote areas and working in areas at risk of bushfire. However, adding to the complexities of safety considerations was that our project was conducted in the time of COVID-19, which necessitated extra hygiene requirements, COVID testing, travel restrictions and the need to immediately stop work when any symptomatic individuals were identified. Ultimately, by implementing our safety plans and processes, we completed the project with no significant safety incidents.

Team work and problem solving

In such complex conditions, the ‘glue’ is good relationships built on trust, shared expectations and objectives, accountability and confidence in each other. This enables collaborative problem solving to overcome challenges or changes in the project. However, contractors often don’t know each other and may be meeting for the first time onsite, so these trusting relationships need to be built quickly.

This requires a level of frankness and transparency among all parties, with honest and open analysis of where things are working well, where there’s room for improvement or where more support is needed.

Particularly in remote areas, it is essential that people don’t feel isolated or alone. Regular drop-ins can help, providing continuity and fresh eyes on site.

Some of the success of a remote project will come down to experience, but just as much depends on good teamwork, regular and open communication, choosing great contractors, and meticulous planning. Not every on-site circumstance can be foreseen, but with these success factors in place, you’ll have a solid foundation and the flexibility to solve challenges on the ground as they arise.

Written by James Butler.

MORE THOUGHT LEADERSHIP ARTICLES

Multipurpose dams: maximum value for money?

When a dam is being considered, there’s usually a primary purpose. But are there also secondary purposes that can benefit the local and wider community? Have you thought about the potential additional economic development that can stem from a multipurpose dam?

Multipurpose dams combine two or more functions of traditional single-purpose dams into one dam infrastructure project. A multipurpose dam may combine storing and supplying water for irrigation, industry or human consumption; flood control; power generation and power storage; navigation; water regulation; environmental releases; climate change resilience; and recreational purposes.

The dam structure will be similar to a single-purpose dam, but the design will incorporate features into the dam and water infrastructure facility to accommodate different purposes. These may take the form of irrigation channels, power generation facilities or navigation facilities. Including various gates or valves can provide greater operational flexibility for floods or environmental releases for downstream community and environmental needs. A single-purpose project can become multipurpose during its planning stage, during operation, or in the long term when re-engineering becomes necessary.

Why consider multiple purposes?

Multipurpose dams are not a new concept; in fact, almost half of all dams are used for more than one purpose. There is a growing trend to consider multiple purposes when developing a dam, for several reasons:

- Dam sites, particularly storage sites, are scarce national resources (i.e. they are not unlimited), so it makes sense to consider how to extract maximum benefit from them when constructed.

- Dam infrastructure may commonly last for up to 100 years or more (i.e. they are considered a long-term asset). A dam represents a genuine long-term investment for the future, and so ideally should be viewed as such and incorporate the potential for flexible use over time.

- Multipurpose dams are very beneficial in developing countries, as the multi-functionality of the dam operations can contribute to a number of development goals simultaneously, such as energy, water and food security, economic development, and climate resilience. In 2016, the International Commission of Large Dams (ICOLD) recognised the importance of multipurpose dams in the release of the ICOLD Bulletin ‘Multipurpose Water Storage – Essential Elements and Emerging Trends’, which rightly links the common global needs of water, food and energy. The sporadic, spatial and temporal distribution of precipitation rarely coincides with demand, making storage essential for food supply, energy production, potable water supply and other water delivery services that depend on sizable, reliable, continuous and efficient supply of water.

- Climate change scenarios predict increasing variability in rainfall, impacting both yields and flood peaks. Droughts will affect agricultural production, and flooding is expected to increase due to more extreme weather events. With many regions of the world experiencing significant water stress, which is expected to be exacerbated by global warming, storage will play an increasingly critical role in bolstering a water system’s hydrological resilience. Dam projects should be designed with this necessity and value of storage in mind. Even in developed countries, we need our dam infrastructure to be ready to adapt to future changes as required. Taking change into account and considering multipurpose approaches will benefit new dam projects as well as projects that modify existing reservoirs.

Looking into the future

Multipurpose water storage projects pose additional engineering challenges when compared to single-purpose projects. Given the longevity of the infrastructure of large storage projects, planning professionals need to develop and implement solutions that will provide adequate flexibility to adapt to changes or to the diverse needs of multipurpose schemes. Scale, site selection and operational characteristics should be assessed through a long-term perspective, incorporating anticipated trends and emphasising adaptability so that future generations will inherit infrastructure that can evolve as the world continues to change.

There is no doubt that this sustainability principle is valid; however, determining how best to implement it in practice is not always easy. It is hard to anticipate and predict what will happen in a century (which is the expected life of many dams), yet this should not stop us during the early stages of the project from trying to assess long-term performance based on potential long-term scenarios (i.e. scenario testing).

Multiple perspectives for multiple purposes

Achieving the best outcome for a multipurpose dam is more likely when planners and engineers work together and closely consider the local community’s needs and the potential benefits to be gained. Both social and environmental needs should be considered, with detailed social and environmental impact assessments conducted.

Applying the principles of Integrated Water Resource Management (IWRM) in the planning process will help promote coordinated development and optimal management of water resources – furthering progress towards goals of social equity, economic efficiency and environmental sustainability. It is important to establish criteria by which to monitor the achievement of the multipurpose objectives and the post-construction impacts on the community and environment. Another important consideration is the manner of operation of the multipurpose reservoir, which will also be critical to achieving the range of its objectives.

What is a multipurpose dam worth?

A key planning challenge in multipurpose dam infrastructure is fully appraising the economic costs and benefits of the project. In many projects there’s a tendency to focus the analysis on the components that provide revenue streams (such as energy and water supply and irrigation tariffs) as these are most easily valued. However, this can underrepresent the project’s value across all of its multipurpose objectives, potentially resulting in suboptimal decision making or difficulty justifying the long-term investment. For example, a fundamental purpose of storage projects is flood mitigation – but flood mitigation does not generate a revenue stream. However, the economic value of flood control to a country (through avoidance of direct and indirect flood damages) often justifies the allocation of funds from the public sector.

Putting this into practice in Samoa

The Alaoa Multi-Purpose Dam in Samoa is a fitting example of the considerations presented above.

Samoa is a small tropical island country in the Pacific, and has been heavily affected by severe tropical storms. In 2012, Cyclone Evan caused extensive flooding and damage to the Apia region, the capital, where most of the population and economic activity is located. With such storms predicted to increase in frequency and severity as the climate changes, the Government of Samoa has adopted a programmatic approach to address climate-change-induced flooding. This includes the new Alaoa Multi-Purpose Dam, sized and designed with long-term climate scenarios in mind and to provide multiple functions. It aims to increase flood protection, improve the current water supply system’s seasonal reliability, and provide additional hydropower via installation of a small hydro facility.

The dam’s design considered multipurpose functions and climate change risks, and included small modifications to provide better outcomes. Climate resilience was ‘designed in’ by incorporating ‘dead storage’, providing sediment flushing capability, increasing the flood capacity, and including a number of gates and valves – all contributing to future flexibility of operation.

The intake to the small hydro station incorporated a station bypass valve for water supply. As well, a low-level outlet and a mid-level outlet were added to increase the operational flexibility of the dam to meet its three purposes. This also enabled both low-flow and high-flow environmental releases, and improved dam safety management. How the reservoir is operated will be significant in achieving the multipurpose functions. The dam’s flexibility will allow future adaptive modification of the operation to align with the changing demands of the reservoir.

The main purpose of the Alaoa Multi-Purpose Dam was flood retention and mitigation. Consequently, as we discussed above, a limited financial analysis could not justify the multipurpose project, yet the broader economic analysis could. However, the financial analysis indicated that the regular revenue stream from the small hydro’s energy production could increase the project’s sustainability once constructed. This revenue stream would contribute to the ongoing operation, maintenance and dam safety activities associated with the multipurpose project’s long-term operation.

Could multiple purposes be incorporated into your dam project?

Whether you are in the planning process or the early design phase for a new dam, consider whether your project could be modified to:

- achieve multiple purposes and increase the benefits of your dam project

- increase operational flexibility to allow your dam to adapt to future changes and demands

- improve the use of water resources for all needs, including the environment

- increase the climate resilience of your dam and the impact of climate change on its multiple objectives.

If you would like to discuss how we can assist you with planning and designing a multipurpose dam, please contact Richard Herweynen, Paul Southcott or Phillip Ellerton.

About the author

Richard Herweynen is Entura’s Technical Director, Water. Richard has three decades of experience in dam and hydropower engineering, and has worked throughout the Indo-Pacific region on both dam and hydropower projects, covering all aspects including investigations, feasibility studies, detailed design, construction liaison, operation and maintenance and risk assessment for both new and existing projects. Richard has been part of a number of recent expert review panels for major water projects. He participated in the ANCOLD working group for concrete gravity dams and is the Chairman of the ICOLD technical committee on engineering activities in the planning process for water resources projects. Richard has won many engineering excellence and innovation awards (including Engineers Australia’s Professional Engineer of the Year 2012 – Tasmanian Division), and has published more than 30 technical papers on dam engineering.

MORE THOUGHT LEADERSHIP ARTICLES

Keeping international projects moving, even when we’re grounded

With no set date for when life will return to usual after COVID-19, nor any guarantee of whether life will ever return to what we previously knew as ‘usual’ at all, there are very few areas in the consulting life in which we can simply say ‘we’ll wait until this is all over’. Life, and projects, must go on.

Although we can’t avoid the disruption and uncertainty that the coronavirus has unleashed, we can increase our resilience and agility. We can also embrace opportunities to innovate and to create new ways (or reinvigorate old ways) to achieve our goals.

Here, Entura’s Environment and Planning team continue to apply their proactive approach to keeping projects alive in the current circumstances, and explain how they are continuing their activities on two international projects despite the travel restrictions that are making it impossible to visit the project sites.

Old ways for new times – Engaging communities in Tonga

For many countries across the globe, the immediate challenge is building resilience to fight through the pandemic. However, for some small island nations that have managed to stay out of the virus’s path so far, such as Tonga and the Federated States of Micronesia, the concept of resilience has a broader context.

Climate resilience is a core objective, as these nations are feeling the increasing impacts of rising sea levels and more frequent and intense weather events. In this context, robust power infrastructure that is suited to extreme weather is one component of greater resilience, as is transitioning from diesel dependence to higher levels of renewables, which builds greater security of energy supply at a lower longer term financial and environmental cost. More access to stable, reliable and clean electricity is also critical for the health, wellbeing and education of local communities, and is the foundation for economic development. Entura has been fortunate to be involved in some meaningful resilience-building projects in the Pacific, supporting many of our neighbouring nations to implement sustainable energy solutions.

However, with a current project in Tonga, coronavirus has thrown our travel plans into disarray. The challenge we’re facing now is how to continue the planning, engagement and environmental activities required by such a project when we can’t physically get there, can’t hold town hall meetings and can’t host information sessions with locals.

While the pandemic is forcing many practitioners to extend and expand their use of digital forms of engagement (such as websites, Facebook, Twitter, ‘Bang the Table’ or moderated ZOOM-based focus groups), some projects are located in communities that do not enjoy easily available or reliable internet or telephone access. In these cases, such as our project in Tonga, we need to think differently about ways to facilitate engagement from a distance.

For the Tongan project, we’re heading back to basics: the tried and tested solution of providing information on paper. Working with the local project management unit, along with our client, we are designing and implementing a newsletter to be printed in the local language and distributed to regulators and communities. It will provide snapshots of the project, latest updates on scheduling, and will even feature some interviews to provide greater coverage of ongoing community engagement.

As the construction company for the project is, like us, unable to travel internationally at the moment, construction is yet to take place. Nevertheless, we are continuing to facilitate all aspects of the project remotely, such as lining up approvals with regulators, and guiding engagement on the ground. With the help of our Tongan counterparts, we can still keep information and updates flowing despite the physical limitations on our involvement ‘in the flesh’.

Buying time and building partnerships in South-East Asia

Just as COVID-19 started closing borders and halting international travel, our team was reaching the culmination of many weeks planning an impact assessment for a large infrastructure project in South-East Asia. Our discipline experts were about to book their tickets and embark on the journey to site to survey environmental and social impacts. However, we placed the site surveys on hold indefinitely to comply with travel restrictions, ensure the safety of our people and contractors, and not risk spreading the virus in remote communities.

This abrupt shift in our plans afforded us the chance to take a breath, reflect on the project and its broader risks, and then develop an alternative plan to keep progressing aspects of the work that could be done remotely. We are now proactively undertaking desktop approval studies and initial public consultation from our desks. We’re ‘buying time’ now to save time later.

When travel restrictions lift and it is once again safe to physically attend the site, we will be ahead of where we would have been pre-COVID-19. We will better understand potential issues and have a more thorough insight into the local and community context. We’ll have already carefully planned our field studies with more targeted approaches. We’ll be better prepared for stakeholder questions that may arise, and will have already considered ways in which the project might manage challenges and risks going forward.

But there’s something more that we’re seeing emerge in this COVID-19 period. We’re finding that the shared need to adapt to trying times and the mutual desire to find workable solutions is strengthening our relationships with our clients, building even greater trust and collaboration, and it is leading to ‘partnership’ relationships that transcend the more common transactional paradigm of client–consultant. We are working closely together to openly discuss issues and options, and to determine how best to manage emerging challenges to benefit the project.

Would this have happened without COVID-19? Perhaps – but under the usual pressure of timelines, expectations, standardised processes and the drive for efficiency, there isn’t often the same flexibility or space to build different qualities and layers in our relationships or to consider potential issues quite so broadly or creatively.

Will the project benefit from the changes made necessary by COVID-19? Probably – despite the difficulties caused by the limitations on travel, it can only be positive to have had the chance to take the time to more thoroughly and holistically consider all the issues and risks before we proceed to field studies and stakeholder engagement.

Will timelines change significantly because of COVID-19? Not necessarily – we will inevitably lose some months by not being able to go into the field, but we will have ‘bought’ some time by compiling a good portion of the project documentation prior to the field studies, so that the time required in subsequent stages is lessened.

Wherever in the Indo-Pacific region our international projects are located, our clients can be confident that we’re seeking all the ways we can – new or old – to keep making progress in these uncertain and complicated times … and to come through them stronger together.

If you would like to discuss how Entura can help you with your environmental or planning project, please contact us.

Don’t let COVID-19 stop your project

A vital part of the success of all projects, whether they are new or operational, is maintaining progress towards milestones and retaining currency in the social and regulatory realms. How can we achieve this during a global pandemic?

With the COVID-19 crisis affecting people and businesses across the globe, employers and employees alike are racing to find normalcy. Fortunately for Entura, we’ve already been working and collaborating virtually for many years across country and state borders, with dispersed office, client and project locations. So, even though our teams are working from home, it is still business as (mostly) usual, in unusual times!

Although COVID-19 hasn’t thrown us completely, travel restrictions have pushed us to think differently about many of our projects and methods. This is the time to explore proactive ways to ensure projects do not come to a grinding halt or fall off a community’s or regulator’s radar.

Keeping environmental and planning projects moving forward

Entura’s environment and planning team works frequently in the field – lakes, forests, roadsides, development sites and many more – so COVID-19 travel restriction have taken a hit at our ability to undertake survey and monitoring programs or to conduct site visits, but it hasn’t led to tools down.

We may miss out on our chance to hit the frosty outdoors this autumn and winter, but there are still many ways that we can and will continue to make progress and deliver value. It’s about thinking creatively about how we can be proactive. And that means finding measures and activities for the short and medium term that will keep the project moving towards the longer term project milestones and goals (without the anticipated longer term extending into the much further horizon!)

For example, there are proactive things we can do to prepare us better for when we can once again visit the site. We have access to a wide range of data and can undertake thorough desktop investigations early in the project. We will then be able to step on site well prepared and looking to fill knowledge gaps or to verify what should be there. That puts us in a better position to be alert to anything unexpected we might find when we’re physically on site in future. Unusual discoveries and observations will be more pronounced. Such approaches can help shorten project timelines post-COVID-19 compared with the inevitable blowouts that would be caused by downing tools completely.

Policy and regulatory reforms are also still happening across the country – some as a result of COVID-19, others associated with larger reform programs to update antiquated legislation. Our discipline experts continue to engage with the regulators and relevant government agencies and authorities to ensure we understand the nuances of these changes and how they may influence the scope of existing and future projects and programs of work.

More proactive, less reactive

The restrictions caused by COVID-19 have highlighted the need to be proactive so that we can be better positioned for the longer term. It’s natural for a consulting paradigm to tend towards the reactive and process-driven, but this is the time to shift such tendencies.

With a future-focus and forward thinking, we can all seek out proactive solutions to keep projects and processes running as smoothly as possible, to meet any milestones that are still feasible, and to do everything that is reasonably possible in the present circumstances that will minimise delays once the pandemic has eased.

This needs to be a shared process. If as consultants and clients we put our heads together, we can develop shared understandings of the opportunities, risks and issues affecting all parts of the project and all the players involved. With team work and good communication, together we’ll find the most innovative and workable solutions, and together we will survive and thrive.

Beyond the immediate

The circumstances of the pandemic are also an opportunity to think beyond the immediate projects on our desks. This is a great time for our clients to review their projects and environmental and social management practices, to be better positioned for the post-COVID-19 future. This could include being more informed about potential risks or thinking through changes that you could make to your management practices to better address ongoing or emerging issues.

In our next article, we will highlight some of the projects we are currently working on, and how we have adapted them in light of COVID-19. We will also dig down into some of the key regulatory reforms happening across the country, and what implications they may have on projects during the COVID-19 period and beyond.

At Entura, we will continue to respond to government measures as they surface, and we will continue to be here to assist all our clients to better understand the opportunities, risks and issues associated with keeping your project alive during COVID-19.

A message from our team to yours

And to finish on a light note – Entura’s environment and planning team has nimbly settled into their new branch offices, from urban Melbournian set-ups to peri-urban workplaces at the foothills of the majestic kunanyi/Mount Wellington in Tasmania. From our team to you or yours, here are a few handy tips which we have found to help with this transition to working from home:

- Stay connected – drop your colleague or manager a line and ask how they are going, and where possible (bandwidth permitting), turn on the video during your virtual meetings.

- Schedule regular team catch-ups, and why not end the week with an optional virtual gathering to kickstart some weekend banter?

- Don’t be embarrassed if your pets or children make an appearance – it helps lighten the mood and may provide the laugh that someone really needed.

- Get some fresh air before you start work – imitate that commute to work by going for a walk or cycle.

If you would like to discuss how Entura can help you with your environmental or planning project, please contact us.

Pictured, clockwise from top left:

- Senior Social and Stakeholder Consultant, Dr John Cook

- Land Use Planner, Bunfu Yu

- Senior Aquatic Scientist, Dr Malcolm McCausland (and friends)

- Team Leader Environment and Planning, Raymond Brereton

- Senior Environmental Planner, Cameron Amos

- Senior Planning and Environmental Consultant, Scott Rowell (about to head out for a ride)

- Environmental Consultant, Rachael Wheeler

MORE THOUGHT LEADERSHIP ARTICLES

What’s the best technology for your pumped hydro project?

For your pumped hydro project to be suited to future energy market conditions, you need to understand the technology options available – because pumped hydro plant is not one-size-fits-all. Let’s go for a deep dive …

Pumped hydro has been around for more than a century, but in recent years it has leapt into the forefront of the quest for energy storage and firming options as the energy sector embraces increasing levels of renewable energy generation. If you want to get the best from a pumped hydro project, it’s important to come to grips with the implications of the different types and combinations of mechanical and electrical machines that have been developed over the long history of hydropower and pumped hydro.

The choices are among fixed-speed reversible pump turbines, variable-speed reversible units (including doubly-fed inverter arrangement), and ternary sets. Each has its own variations and strengths in terms of the services able to be provided to the energy market. But the technologies also vary in costs, housing requirements and performance.

All pumped hydro projects are likely to offer benefits to the market by contributing to operating reserves, reducing spill or curtailment of variable renewable energy, reducing cycling and ramping of thermal plant, lowering transmission congestion and associated costs, and lowering greenhouse gas and pollutant emissions when used to displace thermal generation. But let’s look at the specific pros and cons of each of the different pumped hydro configurations, and how they compare.

Reversible units

Reversible units comprise a single hydraulic machine (turbine-pump), a single electrical machine (motor-generator) and a single shaft. The unit changes rotational direction to switch between generating and pumping modes.

These reversible units come in two different forms: fixed speed and variable speed. The fixed-speed reversible units can’t optimise the uptake of power from the grid in pumping mode, which is important in a grid with the rapid and frequent fluctuations characteristic of high levels of variable renewable energy. However, with a multi-unit arrangement in a power station, additional flexibility during the pumping cycle could be achieved at a premium.

Variable-speed reversible units provide greater efficiency and flexibility and provide different opportunities for grid support than fixed-speed units in pumping mode. However, should all the thermal plants be retired as the energy market transforms, the lack of synchronous machines could become a major issue where rotating inertia becomes scarce. Asynchronous (variable-speed) machines rely on their power electronic controls to provide inertia. While this can be artificially enhanced relative to synchronous machines, it relies on externally provided system strength which may also be lacking in the absence of thermal units.

Based on recent projects in Australia, the cost of electrical and mechanical equipment for variable-speed reversible units is about 30% greater than for fixed-speed units and the construction cost is approximately 10% more. Yet, while fixed-speed units come at a lower cost, variable-speed machines have the potential under some configurations to provide more valuable services in operation, such as variable load during pumping operation, and as long as there is adequate synchronous generation, inertia distributed around the network.

Ternary sets

Ternary sets comprise two hydraulic machines (a turbine and a pump), coupled on a single shaft, with a single electrical machine (motor-generator). This means that the direction of the turbine is the same in generating and pumping mode. They are often the only solution for projects with very high head but they can be applied for lower head projects too. Without having to change direction, little changeover time is needed between modes, making it possible to respond much faster to the grid. There’s also less stress on the machines, which can be individually optimised. The turbine and pump can even operate simultaneously (in hydraulic short-circuit mode), and the turbine can be used to start the pump (further reducing changeover time).

This description makes it sound as if ternary sets are the way to go … but it isn’t that simple.

Many of the elements of the civil works for a pumped storage project are the same whether fixed-speed reversible units, variable-speed reversible units or ternary sets are used. However, the powerhouse structure for ternary sets needs to be taller or wider (as the units are bigger), penstocks and tailrace branch pipes will require an extra bifurcation, and it is likely that the costs involved in hydro-mechanical equipment such as gates and valves will be significantly greater.

The extra construction costs can add up to approximately 25 per cent more than for reversible units. And the additional electro-mechanical equipment could come at a 35 to 50 per cent higher price tag compared to the fixed-speed reversible units. However, countering the increased cost of ternary sets is their likely efficiency gain of 2 to 3 per cent and a faster response time than reversible units are capable of.

The increasing need for fast response

Adopting either variable-speed reversible units or ternary sets appears, on the face of it, to be more expensive than fixed-speed reversible units, but there are mitigating circumstances that make them worthy of serious consideration.

With settlement periods in the Australian National Electricity Market reducing from 30 minutes to 5 minutes, fast response is critical. Both ternary sets and variable-speed reversible units have a big advantage over fixed-speed units in this regard, but fixed-speed units can work with the 5-minute settlement if they are utilised appropriately as part of a pumped storage scheme.

Short-circuit mode

Reversible units and ternary units require similar amounts of power from the grid in synchronous condenser mode. For a 125 MW unit, the grid power required is estimated at about 4 MW.

Some projects investigating the idea of hydraulic short-circuit with variable-speed, doubly-fed inverter machines are currently underway. In essence, a waterway is shared between two units with a bifurcation upstream and downstream of the units. In this case one of the units will operate in generating mode and the other in pumping mode.

What’s the answer?

There’s a lot to take in when comparing the different pumped hydro configurations. It’s generally accepted that variable-speed reversible units and ternary sets have certain advantages over fixed-speed reversible units in a changing energy market. Yet, in some cases fixed-speed units will do the job, and at a lower cost, whilst at the same time guaranteeing synchronous generation if rotating inertia is of essence to grid stability. There’s no clear-cut winner when it comes to pitting variable-speed reversible units and ternary sets against each other. As usual, the right choice will depend on the specifics of your project conditions and what changes you anticipate as energy markets continue to evolve.

If you would like to discuss how Entura can help you with your pumped hydro or renewable energy project, please contact Nick West on +61 408 952 315, Richard Herweynen on +61 429 705 127 or Phillip Ellerton on +61 439 010 172.

About the authors

Nick West is a civil engineer at Entura with more than 18 years of experience, primarily in hydraulics and hydropower. Nick’s skills range from the technical analysis of the layout of hydropower projects to the preparation of contractual project documents and computational hydraulic modelling. Nick was a key team member of the Kidston Pumped Storage Project Technical Feasibility Study and is currently involved in feasibility assessments of pumped hydro options as part of Tasmania’s Battery of the Nation initiative.

MORE THOUGHT LEADERSHIP ARTICLES

Engineering – by humans, for humans

When engineers think about the future, do we get so engrossed in the complex technical problems that we don’t attend enough to the human angle?

Engineers have a reputation, whether rightly or wrongly, for being poor communicators, working obsessively and in isolation, and focusing on the immediate goal rather than its impacts on communities. Often, clichés have a basis in truth. If we are going to shift perceptions, we need to start by thinking about the way we work and the leadership we show to the next generation of engineers.

There’s no way we can predict the major developments, challenges or solutions of the next five or six generations of engineering careers. What we should focus on is what we can do right now to lead change in our profession and our communities – and I think the keys are communication, collaboration and community.

Communication

I recently listened to a podcast in which two energy market experts talked with a power system engineer. They discussed all sorts of technical matters relating to frequency and voltage control. I love those topics, but this conversation was limited and uninspiring because the participants simply didn’t have a common language or understanding.

We need to learn to communicate in ways that a variety of people can understand. That will mean better conversations with the people who can help our work have greater impact, and it will help our communities to appreciate the importance of our work in their lives.

It’s too easy for us as a profession to sit at our desks or stand under our hard hats and luxuriate in how clever we are, and then bemoan how so many people have no idea what we do and don’t value our work.

When things that involve engineers go wrong, a flurry of opinions erupts. Failures such as the blackout in South Australia, or the cladding issues at the Grenfell Towers, or issues with airlines or bridges or dams all lead to our communities questioning and debating engineering practice. Engineers tend to try to stay out of this rough and tumble for fear of being misrepresented. Yet maybe it’s better that we do engage where we can, since being misrepresented on a small issue is better than allowing a groundswell of misguided public opinion due to a lack of understanding of engineering principles.

We need to try to better explain our work and find simple ways to convey the complexities of the decisions that we make.

Collaboration

The world is far more complex now than it was a century ago – but it is impossible to imagine what level and pace of change future generations will experience. If we want to transform our world or help build a better future, we can’t do it by ourselves.

Engineering no longer operates in isolation, if it ever did. We must collaborate across the engineering team and across other professional disciplines to achieve truly effective development for our communities. Sometimes we may need to focus a little less on technical delivery as a primary outcome, and increase our recognition of the value gained by engaging successfully with the communities on whom the project relies for success.

Collaboration makes our work more effective, and exposes us to a wider range of inputs and values that we can incorporate into our designs and processes. Engineering can be a leader but it can also be a facilitator for better outcomes when we draw on, listen to and learn from the other experts involved in other aspects of our projects.

Community

Engineering work almost always benefits more people than merely the one who pays the bill. Much of my work is in connecting wind farms and solar farms to the grid. Mostly my work is paid for by the owner of the farm, and while it delivers direct benefits to the owner through return on investment, it also affects everyone connected to the nearby network. It affects the network service provider and market operator, it pays salaries, and it supplies the clean energy that helps the country reduce emissions and meet its international targets. In other words, my work, which may seem intangible, has tangible effects in the real world.

If we agree that our labours produce real impacts, we need to take better care to fully consider the wider consequences of our work, which often has the potential to cause ‘collateral damage’. We can’t build a road or a wind farm without changing the landscape. When we build a machine, it uses energy and may emit pollutants; and it reduces reliance on manual labour, which may put someone out of a job. There may be a risk to lives, livelihoods or the environment if something goes wrong.

Do we always make decisions about these matters with the community front of mind, or do we place our clients on the higher pedestal? This is a tricky area and I’m not espousing a puritanical approach. However, if we knew in 1919 what we know now about lead poisoning, acid rain, greenhouse gases, scarcity and general sustainability principles, what different choices could have been made?

In a time of automation, we need to think about benefits and risks and how they affect our communities. On one occasion early in my career, I designed a controller to turn on and off a couple of compressors at a power station. I wrote some code to balance the run hours. A few months after the new system was commissioned, I asked one of the operators how the system was going, in terms of the run hours management, and he said ‘you’ve done me out of a job’. I hope he was joking. The task he’d been doing wasn’t particularly important, but there was value in having a person who was in tune with the equipment to take care of it, and there was also value in giving that person dignity through work.

My point is that we must keep our communities foremost in our minds as we go about our work. It’s not just about what we produce. It is the way we work and the people we choose to work with and for. Our influence on the development of the next generation of engineers perhaps has more impact on communities than our actual work outputs.

Through communication, collaboration and community, engineering can be both ‘more human’ and ‘for humans’.

About the author

Donald Vaughan is Entura’s Technical Director, Power. He has more than 25 years of experience providing advice on regulatory and technical requirements for generators, substations and transmission systems. Donald specialises in the performance of power systems. His experience with generating units, governors and excitation systems provides a helpful perspective on how the physical electrical network behaves and how it can support the transition to a high renewables environment.

MORE THOUGHT LEADERSHIP ARTICLES

Becoming the Battery of the Nation

This article appeared first on the International Hydropower Association blog.

How can a small island become a giant battery for a nation? We’re finding the answers in increasing interconnection, developing new pumped hydro and repurposing our existing hydropower assets.

Tasmania is a small island state, with excellent water and wind resources. We’re powered mostly by an extensive hydropower system developed over the last hundred years – supplemented with newer wind developments. We’re connected to Australia’s National Electricity Market by an interconnector running across Bass Strait to the mainland. This has allowed us to trade in the national market for some time now, but as thermal generation progressively retires and Australia embraces greater proportions of variable renewables, the future national market will be vastly different. It will be characterised by low-cost variable renewable energy sources firmed by dispatchable storage and generation.

With Tasmania’s fantastic natural resources, established hydropower system and expertise, we want to be the ‘Battery of the Nation’, offering the generation and the storage and system support needed to help Australia achieve a clean, reliable, affordable energy future. Our Battery of the Nation vision is shaping up to be one of the most credible, competitive and coordinated solutions, able to be built in stages, aligned to market drivers.

In a nutshell, the Battery of the Nation means generating more renewable energy from our hydropower and wind assets, developing more storage solutions in the form of pumped hydro and building more interconnection to the mainland so that we can get our product to the national market to quickly and reliably support variable generation.

With the support of funding from the Australian Renewable Energy Agency (ARENA), we’ve been making progress towards this vision on a number of fronts.

Connecting the battery

Batteries aren’t much use if they’re not connected, so we need more interconnection to mainland Australia to get the power to where it’s needed. The initial business case for a new, second interconnector between Tasmania and mainland Australia shows it stacks up, and federal funding has recently been secured to fast track this 1200 MW interconnection project, known as Marinus Link.

Priming the pump

Around the world, significant investment is being made in new technologies such as grid-scale batteries and solar thermal projects, yet pumped hydro remains the most viable technology for longer term storage (greater than eight hours). Our state has significant pumped hydro potential and our existing hydropower assets offer excellent potential to repurpose and create cost-effective pumped hydro. We’re filtering down the possible pumped hydro options to identify around 2500 MW of future potential. The three most promising sites offer between 12 and 31 hours of storage and would cost around AUD 1.5 million / MW to develop. Further feasibility investigations will identify which one of these three will be the preferred option that can be ready to take advantage of more interconnection.

Redeveloping existing assets

We are also focusing on how to get the most out of our existing hydropower assets by repurposing and futureproofing them for a transitioning electricity market. The Tarraleah scheme in Tasmania’s central highlands was commissioned in the 1930s and our studies have been considering whether the scheme should be progressively refurbished or redeveloped. Redevelopment would more than double the scheme’s capacity from 104 MW to up to 220 MW – contributing to Battery of the Nation targets. By converting the station to flexible and fully dispatchable operation, instead of just baseload, it could flexibly boost output at times of high market demand and provide the ancillary services likely to be increasingly valued in the market. It is also expected to have flow-on benefits for the entire cascade of power stations below it.

We are also continuing major refurbishment and upgrades of other existing hydropower assets so that we can get more generation, efficiency and longevity from these assets to support our plan to become the Battery of the Nation.

Benefits for our island and the nation

The Battery of the Nation vision offers economies of scale and diversity by combining flexible, reliable renewable energy resources with cost-competitive, large-scale storage that can be built in stages, aligned to market drivers.

Battery of the Nation is designed to serve and support our local and national communities. Across the nation it will contribute to achieving lower power prices, reliable and secure energy supply, and meeting sustainability targets. It will also offer specific benefits to Tasmania through energy security and economic stimulus.

Battery of the Nation is a bold and bright vision to unlock our potential to contribute to the nation. It’s an example of how to reimagine hydropower and storage for the new market paradigms of a shifting energy future.

Safer dams are a matter of priority

Examples from around the world demonstrate the devastating consequences of dam failures. Safety must be every dam owner’s key concern, but how should action be prioritised across a large portfolio of dams?

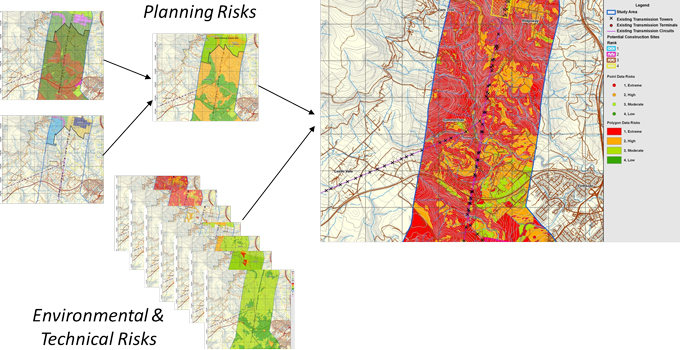

To prioritise effort and resources to achieve the best safety result across a whole portfolio of dams, you need a portfolio risk assessment (PRA). A PRA determines the risk position of the dams based on known information, identifies any information gaps, develops a strategy to close these gaps, and then determines the most effective actions to decrease any risks.

APPLYING PRA TO A LARGE AND COMPLEX PORTFOLIO

Entura has supported dam owners and water managers across the Indo-Pacific region with PRAs, but our most extensive application of the PRA process has involved the 54 large dams of our parent company, Hydro Tasmania.

Hydro Tasmania is Australia’s largest water manager and is committed to ensuring that the risk of a dam failure is very, very low across the entire portfolio. Across so many dams, clear priorities are needed to focus dam safety efforts and human and financial resources.

It has now been 20 years since Hydro Tasmania’s PRA journey began in 1999, so it’s timely to reflect on its outcomes.

With so many dams of greatly varying types, ages and heights, the PRA across Hydro Tasmania’s dams was always going to be complex, and needed to be staged. The first step was a small pilot study on five selected dams that represented the range of potential risks within the broader portfolio.

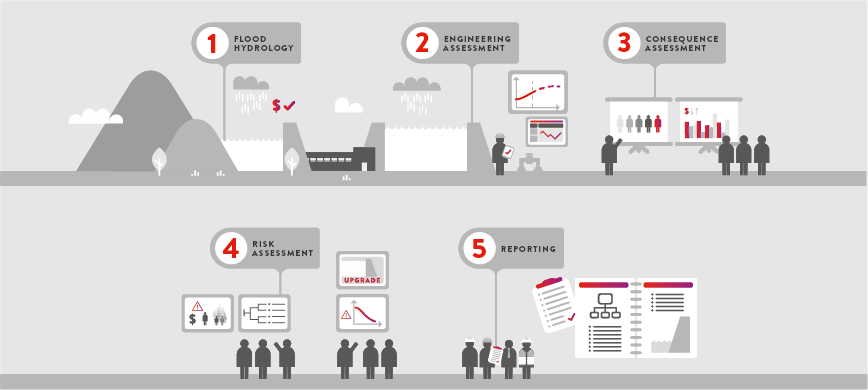

During the pilot study, the five steps of Entura’s PRA process were defined:

This methodology was applied across Hydro Tasmania’s dams portfolio, and an average of eight dams were added to the review each year.

By 2005, the initial ‘baseline’ assessment of the full portfolio was complete. The focus of the dam safety program has now moved to investigation and implementation of upgrades, and the communication of outcomes to senior management.

The PRA process has increased the focus on potential failure modes and risk as drivers of the dam safety program and as the basis for deciding priorities for allocating operational and capital resources.

DETERMINING PRIORITIES THROUGH A RISK FRAMEWORK

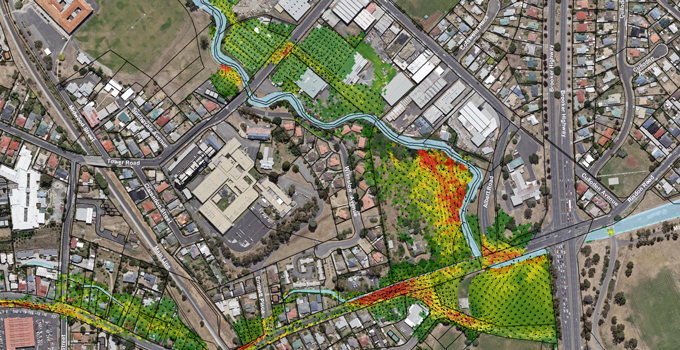

Entura’s PRA process reviews the consequences of failure of a dam by looking at the impact that it may have on downstream populations and infrastructure. The engineering assessment considers the effects on dams of extreme events such as floods and earthquakes, taking into account the specific site conditions. Combining the chance of failure and the resulting consequence determines the level of risk.

Hydro Tasmania assesses, prioritises and mitigates risks across the business using an integrated business risk management program, and the dam PRA feeds into this overall risk management approach. A dam’s assessed risk rating across common tolerance criteria drives the risk management response. The assessed dam risks are plotted together on a chart to provide a risk profile for the whole portfolio. This allows dam safety risks to be compared, understood and communicated readily throughout the business in a similar way to all other business risks.

The initial objective of the dam safety program is to reduce all the risks categorised as ‘high’ or ‘extreme’ as soon as practical , and then to continue with a program of investigations and capital works to diminish risks even further. Actions for dams lying in the higher risk zones did not wait for completion of the PRA, but were initiated as soon as risks were identified.

Some cost-effective and expedient risk-mitigation was achieved by identifying and implementing ‘quick wins’. These early actions reduced the overall portfolio risk while more complex mitigation plans were being developed. In some cases the ‘quick win’ actions have even provided the ultimate solution. In other cases, more major works have been required.

PROGRESSING THE DAM SAFETY JOURNEY

The PRA process has substantially benefited Hydro Tasmania’s dam safety program, by improving understanding of the dam portfolio, underpinning a strong strategic plan for addressing risks, improving surveillance and monitoring, and considerably strengthening dam safety emergency planning and warning.

However, this isn’t the end of the dam safety journey. Knowledge of any dam is never complete, and it is critical for dam owners to remain aware that not every failure mode may necessarily have been identified in a baseline study that relies on existing information. There may still be a level of uncertainty about the ‘unknowns’.

For Hydro Tasmania’s PRA, identifying these uncertainties enabled development of a prioritised list of investigations necessary across the portfolio. These detailed investigations have been critical to the development of the dam safety program, by confirming any potential failure modes identified in the PRA.

The list of potential failure modes of a dam portfolio must be rigorously and regularly reviewed, and investigations to reduce uncertainty about the portfolio should be ongoing. New methods and techniques for analysis are being developed all the time, and it is important to understand how these may change existing risk assessments. As well, the safety and risk-level of a dam can change as dams age, or when there are changes to the way the dam is managed.

It is also important to realise that the capital works program for dam safety risk reduction across a portfolio must remain flexible and be actively managed to respond to new or changed risks, new developments in the field of dam engineering, shifts in business priorities, delays to projects, and new developments in risk management.

The sheer number and variety of types, ages and consequence categories of Hydro Tasmania’s dams made Hydro Tasmania’s PRA a challenging process, but the benefits are substantial. The baseline study completed in 2005 is not the end of this journey, which continues to prioritise actions, reduce risks and enhance safety across the portfolio.

If you would like to discuss how we can assist you with assessing your dam risks, developing a resource-effective and comprehensive dam safety program, or applying the same PRA process to other key assets, please contact Paul Southcott, Richard Herweynen or Phillip Ellerton.

About the author